FARMINGTON — The Sunday opening of the Biomass Central Heating Plant on the campus of the University of Maine Farmington was a celebration — a celebration of wood and heat, hot water and hope — a return to the simple, earlier times before fossil fuels and peak oil and climate change.

Sunday was a day that celebrated sustainability and what thinking locally and buying locally really means in Maine.

“This energy fits into the local, regional and economic landscape,” said Luke Kellett, UMF sustainability coordinator and assistant professor of anthropology. “Visitors can understand how the journey of a single cut tree that is chipped, is carried in a truck, is stored in the bunker below here and eventually gets burned and turns into a hot shower for a freshman at UMF.”

The plant, which will consume 4,000 tons of locally sourced hardwood chips a year, replaces 95 percent of the 390,000 gallons of fossil fuel that was burned annually to heat the campus. It is the largest biomass hot water heating plant in the state of Maine. There are more than two miles of heat lines that carry the hot water from the plant throughout the campus.

“The forest is the poor man’s overcoat,” University President Kathryn Foster said to visitors Sunday prior to the ribbon cutting that formally opened the plant. “We stand today at the University of Maine at Farmington’s new overcoat fueled by the forest of Maine, authorized by the University of Maine system and permitted by the town and village boards.”

Foster said environmental stewardship is a core value in the classroom and in campus life. The new $11 million biomass plant, which takes its wood chips from a 50-mile radius of Farmington, is heating and providing hot water to 23 campus buildings.

“This is outstanding for the university, for the community and for the state,” Foster said in an interview before the ribbon cutting. “This heats the campus together with geothermal heat, so we’re heating almost 90 percent of the campus in Farmington with non-fossil fuel, which is a great achievement for the University of Maine System. It includes all of the housing for students.”

Foster said the university borrowed the $11 million to construct the biomass system with no money up front.

“We will pay back the plant with the savings over and above the cost of oil,” she said. “We’re going to realize over $800,000 a year over the cost of what it was for oil, and then we’ll use that to pay back the plant.”

The bond was initiated in 2015 with an expected pay off in 10 years, and the life of the plant is 30-plus years, Foster said. Payback for the first 10 years will go into paying off the debt; after that the savings will be applied to campus operations, she said.

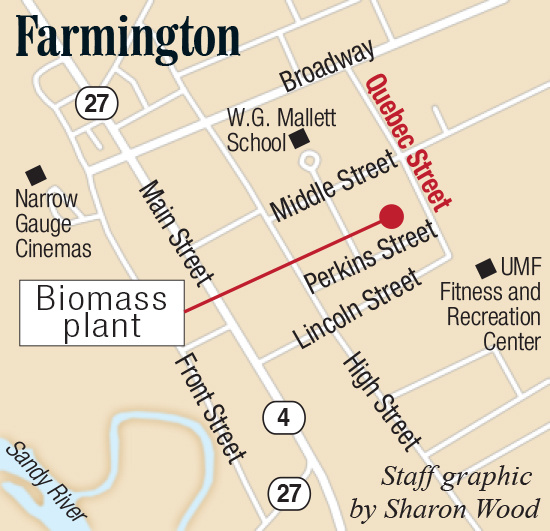

The 5,885-square-foot central heating plant was proposed after Summit Natural Gas plans to extend a pipeline to Farmington were delayed. The project was approved in January 2015.

During tours of the plant, Jeff McKay, director of facilities management at UMF, said water is heated to about 210 degrees and distributed to campus. Ash in small quantities from the boiler is composted locally as a lime agent, he said.

“The humming that you hear,” McKay said to the large tour group, “that’s the only noise that this plant creates. All you hear right now is the fans that blow air to have the correct combustion temperature.”

Wood chips arrive at the plant in a trucking agreement with Cousineau Wood Products of North Anson and are deposited in a large chip hopper. The product is all hardwood with about a 40 percent moisture content, McKay said.

From the hopper the chips are moved with an auger onto a conveyor system, which loads the boiler with wood chips as needed to maintain the correct temperature in the boiler.

The plant and campus conversion project were developed by Trane U.S. Inc. working with Dirigo Architectural LLC.

In his remarks Sunday, Norm Fournier, a member of the University of Maine board of trustees, said the new plant is a “giant leap forward” in the university system’s goals for sustainability.

“It has been our board’s challenge to try the course of both energy cost reduction and environmental stewardship,” Fournier told the assembly gathered outside the plant. “This project is a shining example of the success of that effort. This project is the right thing to do.”

Doug Harlow — 612-2367

Twitter:@Doug_Harlow

Send questions/comments to the editors.

Comments are no longer available on this story