SKOWHEGAN — It doesn’t take long to get to $165 million when you’re replacing big pieces of equipment — and providing up to 500 new construction jobs along the way.

That was the message Friday during a tour of the Sappi North America mill and grounds in Skowhegan, where officials said 90 percent of the upgrades to paper machine No. 1 will be a switch to making packaging material for consumer products.

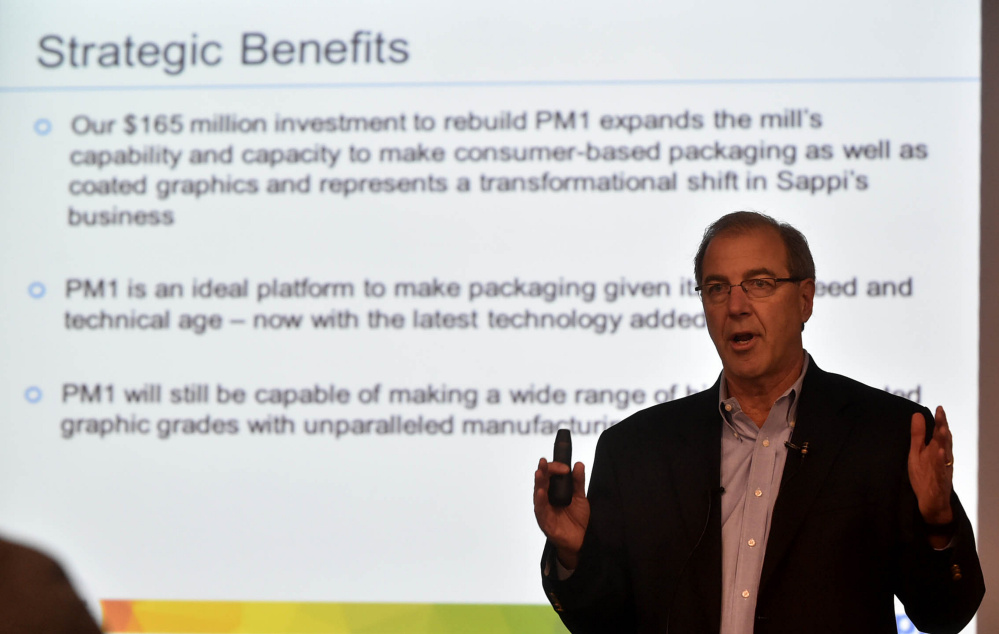

John Donahue, vice president of procurement and the packaging project leader, said the move represents a transformational shift in Sappi’s production line.

“Paper machine 1 is an ideal platform to make packaging, given its size, speed and technical age — now with the latest technology added,” Donahue said during a preview of the site tour.

Tony Ouellette, managing director at the Sappi Somerset mill, said the machine initially will be making the same products — graphics printing products — then will start trials for the packaging market.

“Eventually 90 percent of the product line will be in the packaging,” he said.

Packaging is to include such things as toothpaste boxes, cosmetic products packaging and the white packaging that goes into a variety of home products.

“We will have a lot of versatility when all is said and done, but the main product line we expect to produce is called folding carton,” Ouellette said, referring to the type of packaging used for consumer goods such as tea packets, high-end facial tissues and dry goods packaging.

“Think of any packaging that is all white, both inside and out,” he said. “We will continue to use our bleached fiber to produce what is often referred to as solid bleached sulfate in the packaging world.”

The $165 million investment announced earlier this week to rebuild the No. 1 paper machine — one of three papermaking machines at the site — expands the mill’s capability and capacity to make consumer-based packaging as well as the coated paper the company is known for.

Sappi already makes some soup can labels and packaging for pet food on its other two machines, but with the new investment, the company can expand its product line in what it calls Sappi 20/20 Vision. New paper products to come out of the mill on U.S. Route 201 could include grease-resistant, multi-wall bags for dog treats; labels for such products as food jars; and a wide range of solid, bleached sulfate paperboard for bathroom products such as bar soap and hand cream.

The product line is slated to go live in April 2018.

Donahue said with the changing world of wood harvesting and papermaking, the changeover at paper machine No. 1 will be like adaptations and retooling that have happened in the auto industry.

The Sappi Somerset mill employs about 750 people, 80 percent of whom are represented by four trade unions — United Steel Workers; the International Association of Machinists; the International Brotherhood of Electrical Workers; and Security, Police and Fire Professionals of America.

Sappi Limited, the company that owns the Sappi North America paper mill in Skowhegan, announced the $165 million paper machine rebuild project Wednesday at the Somerset County facility. It described the “significant investment” in Maine as resulting in “further enhancement of offering to graphic paper customers” with a 180,000 metric ton capacity increase.

Sappi Fine Paper North America announced in August that it also would invest $25 million over the next year in new equipment in the paper company’s wood yard off U.S. Route 201, adding as many as 100 temporary construction jobs for that project.

Ouellette said at the time that the equipment investment, coupled with a $60 million capital investment in equipment and environmental safeguards already put into the Somerset plant since 2011, means the South Africa-based company is committed to the region for the long haul.

Sappi’s Somerset Mill was built in 1976 as just a pulp mill. Sappi — originally short for South African Pulp & Paper Industries — purchased the S.D. Warren Co. from Scott Paper Co. in 1994 and is actually two mills — one for pulp, one for paper making.

It is a publicly traded company with about 12,500 employees worldwide, 2,100 in North America and about 1,200 in Maine, including the Westbrook mill.

During a guided tour of part of the 2,500 acres that the mill covers, Ouellette said the company remains the largest maker of coated paper in North America, producing about 2,200 tons a day.

The tour Friday began in a 30-to-50-acre woodyard, where a huge portal crane grappled 10 cords of tree-length wood at a time. The round logs are fed into a big wood chipper. Processed pulp fiber — made from a mixture of soft hardwood, depending on the recipe — enters the paper mill underground from the pulp mill power house to the paper machines. The mixture is fed into a machine that presses and forms the mix into sheets.

There is a wet end and a dry end to the process that takes place on each one of the three paper machines, working in about 1,000 feet of space, 24 hours a day, seven days a week. The process is a series of huge rollers, feeding the wet pulp to form sheets of paperlike material that is squeezed dry, reusing the excess water and liquid mix from previous runs, into rolls of paper for glossy magazines, catalogs and direct mail inserts.

The sheets next are coated with latex paint and pigment in the machines, which stand in 75-foot-tall buildings. The whole operation is monitored in control rooms with computers and televisions watching every step of the way to a finished product — a 285-inch roll, or log — of white coated paper.

The logs are cut into shipping size and shipped to market, mostly by rail, Ouellette said.

Doug Harlow — 612-2367

Twitter:@Doug_Harlow

Send questions/comments to the editors.

Comments are no longer available on this story