Dory Waxman is creating opportunities for immigrants to Maine and helping to revive a lost vocation in the state, one stitch at a time.

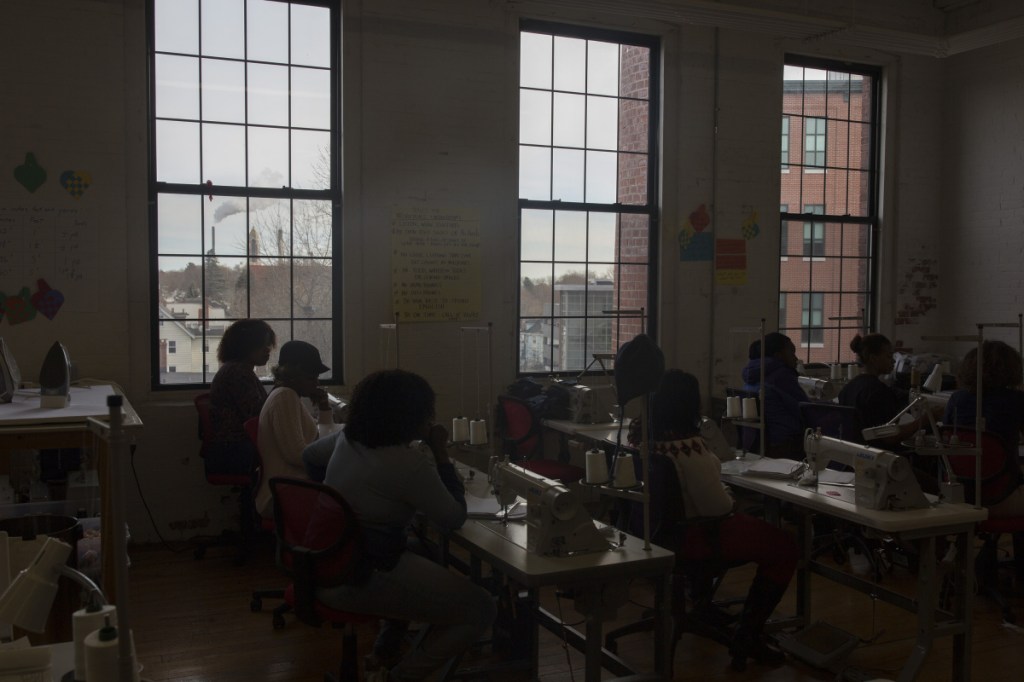

Waxman, the founder of Old Port Wool & Textile Co. in Portland, operates a free nonprofit school in Westbrook that teaches industrial sewing primarily to refugees, asylum-seekers and other immigrants. The school has been operating since 2015 and recently expanded its class size to 16 students per 16-week course.

The school and its graduates have been quietly building a stellar reputation among Maine’s “Made in the USA” clothing and accessories industry, which has seen a recent resurgence after decades of decline. Maine-based companies that currently employ Old Port Wool & Textile School for Stitchers graduates include American Roots of Westbrook, Angelrox of Biddeford and Hyperlite Mountain Gear of Biddeford.

“We try to make them ready to go out into the workforce,” Waxman said.

The school does not charge students to attend. It relies on grant funding to operate, and it recently received important accreditations from the state Department of Labor and Maine Quality Counts that will allow it to access additional funds.

Waxman said she also is applying for 501(c)(3) nonprofit status so the school can engage in private fundraising efforts. She plans to name the organization Common Threads of Maine.

“There’s a big need for textile operators in Maine. This is something that we can bring back home, and that’s what it’s all about,” Waxman said. “But we need to make it financially sound so we can just do it and grow it.”

Many of the students have prior sewing experience but have never worked on industrial machines. Some need help learning English, or how to convert centimeters to inches. The school teaches all of those things.

A classroom map shows students’ native countries.

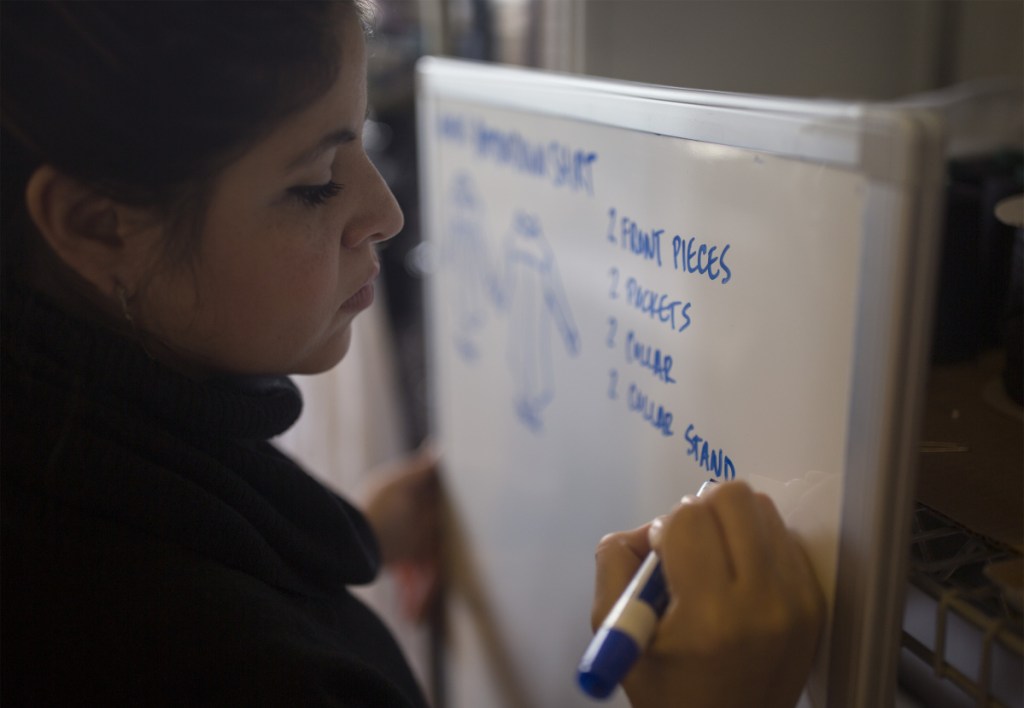

During a recent classroom session, instructor Giselle Larios was showing the students how to construct a woman’s button-down shirt. Larios said classroom projects are designed to cover all of the major skills that would be required by a typical clothing manufacturer.

“There are some pretty basic sewing techniques that are used on most everything,” she said.

SKILLED SEWERS IN DEMAND

John Schafer is director of operations at Hyperlite, which makes backpacks, tents, shelters, outerwear and outdoor accessories. Schafer said the school is helping to rebuild an essential workforce in Maine.

His company already has hired four of the school’s graduates and is eagerly awaiting the current group’s graduation in December.

“I’m planning on hiring at least five folks from Dory’s current class,” Schafer said. “We have lost a whole generation of machine operators. We’re struggling to find skilled sewers for our business to accommodate our growth.”

According to federal labor data, there were 630 sewing machine operators in Maine in 2017 with an hourly mean wage of $13. But the occupation is expected to decline nearly 24 percent between 2014 and 2024, according to Maine labor analysts.

Giselle Larios shows her class on Nov. 15 how to construct a woman’s button-down shirt. A Biddeford company has already hired four graduates and plans to recruit another five.

Anaam Jabbir, one of the school’s first graduates back in 2015, is now head stitcher at American Roots, which makes blankets, hoodies, jackets, scarves and other products. She also is union president at the company.

Jabbir said the school for stitchers helped her build on the skills she had learned as a seamstress in her native country of Iraq. The biggest challenge was learning how to work on industrial sewing machines, she said, which are a lot different from the ones people use at home.

“In Iraq, I just (did) a lot of alterations,” Jabbir said. “This school has helped me a lot. They showed me how to do a vest, jacket, pullover, and then I worked with the industrial machine. … Now I feel mechanical.”

INTEGRATING MIGRANTS

Current student Makenga Tshibwabwa said she heard about Waxman’s school from a friend and decided to check it out. Tshibwabwa also has sewing experience but said she has learned that there are significant differences between how sewing is done in the U.S. and in her native country, the Democratic Republic of the Congo.

“I know our African way, so I wanted to come and learn the new technique,” she said.

Another student, Angolan immigrant Margarida Keta, said she came to the school because she loves to sew, and she hoped it would help her improve her skills.

Giselle Larios, right, works with student Mangudi Dasilva. Those with experience often find differences between industrial sewing machines in the U.S. and the techniques they learned at home, and it’s useful knowledge to have. “We’re struggling to find skilled sewers,” says John Schafer of Hyperlite in Biddeford.

Keta said Larios, her instructor, is an excellent teacher who is knowledgeable and patient. She also gave high praise to Waxman.

“She’s an amazing, amazing woman,” Keta said. “It’s not easy, this project she started with us, but I hope this will continue and that she will give (more) women opportunity.”

Waxman said one of her motivations for running the school is that she wants to ensure Maine remains a vibrant and healthy place full of economic opportunity for her children and grandchildren.

She said an important step to securing that economic future is integrating Maine’s immigrants into the workforce.

“If we can improve the quality of life for the new Mainers coming in, that’s what we should be doing,” Waxman said. “They are our workforce. This is Maine. No matter what people say about immigration and refugees and asylum-seekers coming in here, they are who we are.”

Copy the Story Link

Send questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.